Invisible Noise and System Failures

How many times have you had the problem where your equipment temporarily lost communication, had faulty readings or system failures?

Machines today use Ethernet ports with remote access for operations such as uploading programs, control and diagnostics. What is the best approach for operators using Ethernet ports in conjunction with single or multiple variable frequency drives (VFDs) and servo drives?

The Challenge

It can be challenging for OEMs, system integrators and distributors to find “invisible noise.” Unwanted EMI and RFI noise can degrade the performance of communication systems and cause false triggering and faulty readings in sensor circuits. Such noise can also cause incompatibility and compliance problems.

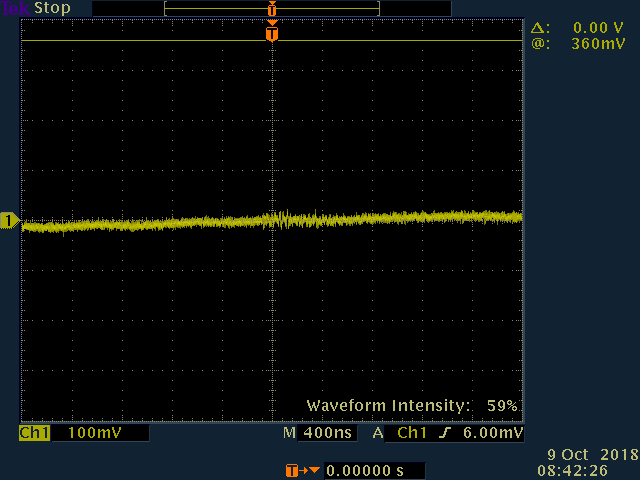

Measurement of ambient noise of an Ethernet port with power off.

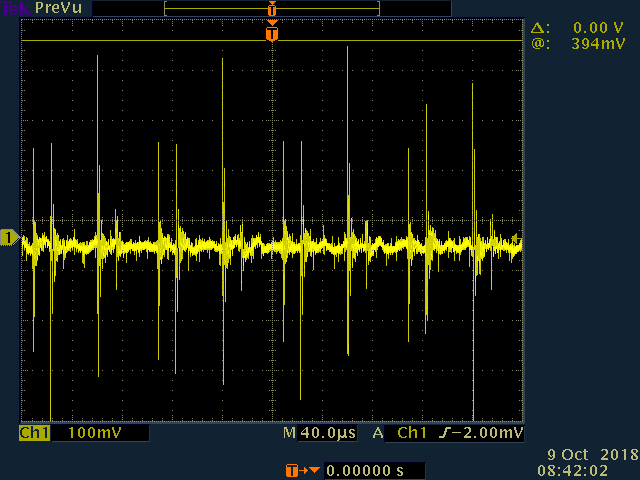

Measurement of an Ethernet port with the VFD powered on; without using an EMI filter. The switching frequency of the VFD negatively affects the quality of the Ethernet port, increasing the risk of communication system failures, which defeats the purpose of the Ethernet port.

The Solution

Using an Enerdoor EMI filter in systems utilizing single or multiple VFDs drastically reduces EMI noise on the Ethernet port, reducing the possibility of interference in communication systems.

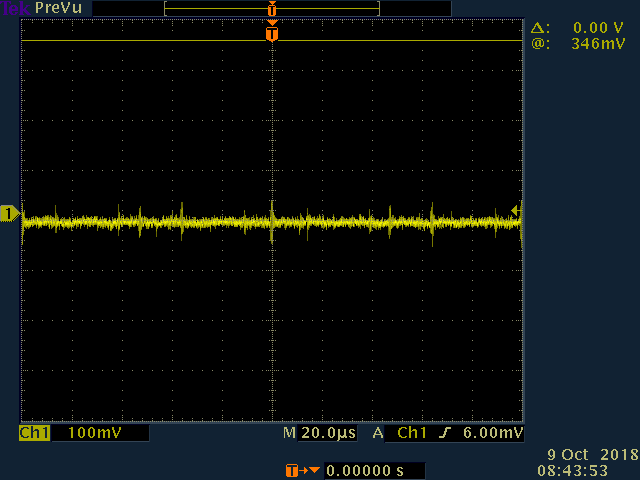

Measurement of an Ethernet port with the VFD powered on; while using an Enerdoor EMI filter.

About Enerdoor

Enerdoor’s unique combination of EMI-RFI filter manufacturing and decades of field-testing experience utilizing the Enerdoor EMC mobile laboratory, has allowed us to become an industry leader in eliminating high frequency noise and harmonics and protecting motors from over voltage transients and spikes.

Previous Article